|

|

| |

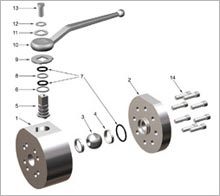

120 Series Ball Valves

- Available in Multi Ports with 3-way, 4-way

- Stainless Steel and Brass construction

- Bi-direction Flow

- Integral ball stem

- PTFE seats

- Two-piece seat fully encapsulates the ball

- Minimum dead space is easily cleaned

|

|

|

| |

210 Series Ball Valves

- Compace Design with two piece Hexagon body

- Stainless Steel and Brass construction

- Standard Butterfly handle

|

|

|

| |

SBVH 360 Series Ball Valves

- Various flow Control

- Blowout proof stem

- Fire safety design

- Handle indicates the flow direction

|

|

|

| |

DIN Type Ball Valves

- Stainless Steel and Carbon steel construction

- POM-Mo S2 seats

- No glands therefore no manual readjustment of seals required

- Full flow passage

- Easy operation

|

|

|

| |

SBVF 360 Series - High Pressure Forged Ball Valves

- Compact design (2way or 3way)

- Handle indicates flow direction

- Panel mountable

- 316 Stainless steel and brass construction

- Low operating torgue

- Adjustable stem seal can be maintained in-line

|

|

|

| |

Trunnion Ball Valves

- 2-way or 3-way design

- Employs spring-loaded seat for high cycle

- Trunnion bearings for longer cycle life

- No packing to adjust

- Manual or pneumatic actuation

|

|

|

| |

Swing Out Ball Valves

- Floating Ball design

- Spring-loaded seat

- Blow out proof stem

- Fire safety design

- Anti static design

- Stainless steel construction as standard

- Live loaded Stem packing

|

|

|

| |

| Back to top |

|

| |

| |

- Stainless Steel, Duplex, Carbon steel consruction

- Blow out proof stem

- Floating & Trunnion mounted Ball type

- Fire safety design

- Anti static design

- Designed according to ASME B16.34 and API6D

- Flanged &Socket weld connction (ASME B16.5/ ASME B16.11)

|

|

|

| |

| Back to top |

|

| |

| |

- Stainless Steel and Carbon steel Consruction

- Blow out proof stem

- Fire safety design

- Locking device available

- SAE J518 & ISO 6164 Flanged end connection

|

|

|

| |

| Back to top |

|

| |

| |

- Stainless Steel Consruction

- Locking device

- It can prevent various accident caused by inappropriate operations of unauthorized or unskilled persons in construction, inspection and running piping work

|

|

|

| |

| Back to top |

|

| |

| |

- 316 stainless steel and Brass construcion

- Straight-though flow path

- One-piece body

- Replaceable plug assembly

- Easy to clean and maintain

- Viton O-Ring seat and seal

|

|

|

| |

| Back to top |

|

| |

| |

- Non-rotating stem tip

- Straight-through orifice for maximum flow

- Stem dust seal protects threads from external contamination

- Replaceable seals, seat & stem tip

- Panel mounting option

- Gauge port option

|

|

|

| |

| Back to top |

|

| |

| |

Integral Bonnet Needle Valves

- Straight and angle patterns

- Stainless Steel and Brass construction.

- Panel Mountable

- Metal seat or soft seat

- Variety of connections

|

|

|

| |

Union Bonnet Needle Valves

- Panel moutable

- Non-rotating stem tips

- Variety of stem tips

- Variety of end connections

- Straight and angle patterns

|

|

|

| |

High Pressure Needle Valves

- Stainless steel construcion as standard

- PTFE packing standard, optional graphite

- Externally adjustable

- Variety of end connecions

- Backseat stem design prevents stem blowout

|

|

|

| |

Intergral Bonnet Bar Stock Needle Valves

- Straight and angle patterns

- Stainless Steel construction

- Panel Mountable

- Metal seat or soft seat

- Variety of end connections

|

|

|

| |

| Back to top |

|

| |

| |

Check Valves

- Stainless and Brass Construction

- Variety of end connection

- Poppet design

- Viton O-Ring seat. PTFE seal

- Variable fixed cracking pressure springs

|

|

|

| |

High Pressure Check Valves &

Adjustable Cracking Pressure Check Valves

- In-Line pattern

- Adjustable and fixed Cracking pressure

- Stainless and Brass Construction.

- Poppet design

|

|

|

| |

| Back to top |

|

| |

| |

Manifold Valves

- 2valves, 3valves, 5valves instrument manifolds

- Stainless steel construction

- MSS Flange connections available

- Graphite packing available.

- packing below threads to prevent lubricant washout

|

|

|

| |

Gauge & Gauge Root Valves

- Non-rotating stem tip

- Multi-port design

- Packing bolt permits stem packing adjustment

- Stainless steel and Monel Construction

- OS &Y bonnet and Block & Bleed style available

|

|

|

| |

| Back to top |

|

| |

| |

- Angle pattern

- Stainless steel construction

- Pressure settings are externally adjustable while the valve is in operation

- Lock wire feature secures the adjusted presure setting

|

|

|

| |

| Back to top |

|

| |

| |

- Compact design

- Open and closes quickly

- Straight and angle patterns

- Panel mountable

|

|

|

| |

| Back to top |

|

| |

| |

- Process interface in one compact ball/ needle/ ball valve assembly

- 2,3-piece bolted Body or 1-piece forged Body construction.

- Flange connections in accordance with ASME B16.5

- Blowout proof stem

- Fire safety designed

|

|

|

| |

| Back to top |

|

| |

| |

- Stainless Steel and Carbon steel construction

- Compact for convenient installation

- Male NPT and SAE end connections

- Size range from 1/8 in ~ 1/2 in tubing and piping systems

|

|

|

| |

| Back to top |

|

| |

| |

- Stainless Steel Construction

- Safety system shutoff device

- Variable connection size

|

|

|

| |

| Back to top |

|

| |

|